|

|

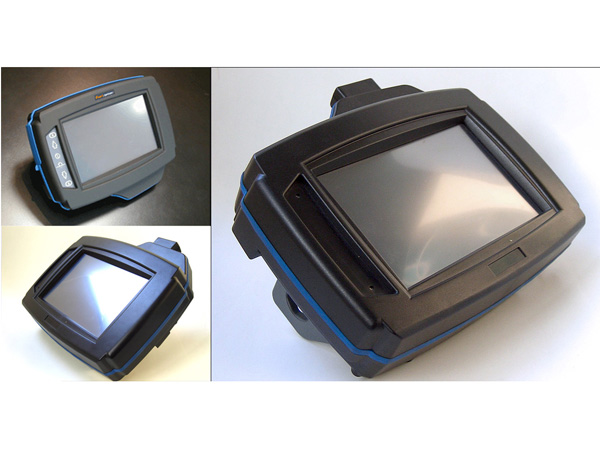

Case study hand-held device sector – IP 65 SAT NAV DEVICE |

THE CHALLENGE

When Swarco Mizar came to us, from the very beginning it established three essential objectives for the realization of the project: quick realization times, low costs and product innovation. The scope of this company, leader in the ITS sector (Intelligent Transport System) and specialized in the development of traffic and transport monitoring and control systems, was to launch on the market a new sat nav device for urban and long-distance transport vehicles: RoadRunner.

The company had won a public procurement so the new product had to be created in a very short time to meet the deadline indicated in the project and it was necessary to keep the costs as low as possible, focusing on design choices aimed at making them competitive being as the end clients were public authorities.

THE SOLUTION

Design

At the first technical meetings between our product designers and the company, a fundamental aspect was established which was to condition the concept and the engineering of this sat nav device: the IP65 protection rating of the whole object, so as to obtain a reliable, latest generation casing to hold powerful electronics.

The public transport vehicles on which these sat navs are installed are washed with steam cleaners which do not control the direction of the water spray which is why the IP 65 rating is of fundamental importance. The IP classification refers to international standard IEC 529 for the degrees of protection provided by enclosures: the first digit always indicates the degree of protection against the ingress of foreign objects while the second digit refers to protection against the harmful ingress of water. The IP 65 rating guarantees protection of the equipment against harmful dust deposits and water sprays from any direction which could damage correct operation.

This requirement immediately pushed us towards the development of an appliance with a compact, attractive and user-friendly design for the end user but with great attention to the technical requirements concerning penetration protection and safety.

So, taking into consideration the volumes of the components and how these need to be positioned inside the device, a series of high-quality photorealistic images were made to give an idea of the finished object. Once approval was received from the client, Swarco Mizar, with whom constant interaction was established in order to make the best qualitative and design choices for the appliance (Roadrunner), we moved onto the engineering stage.

Engineering

During the digital development stage of the design, our engineers modelled each element of the product three-dimensionally using CAD Solidworks software in order to check for any interferences which had not been noticed in the previous design stage but essential for correct engineering of the casings.

The sat nav device is made up of two external shells, a cable gland, an o-ring and a series of gaskets (essential for guaranteeing the IP rating) which were perfectly adapted to the volumes of the internal functioning components such as the GPS modules, wi-fi connection system, anti-glare screen and touchscreen. The result was a geometric structure capable of giving an impression of quality and functionality of a watertight and dustproof appliance.

Thanks to the overall vision of the project guaranteed by the experience of our technicians, really accurate drawings were made which were already perfectly optimized for injection moulding. In this way the industrialization times were very quick, without the need for modifications in the following prototyping and mould engineering stages.

Prototyping

Once the geometry of the parts had been completed and the virtual models approved, we carried on with the realization of the stereolithography prototype to check the functionality and assembly of the RoadRunner. This allowed us to carry out a last and fundamental check aimed at pinpointing any critical aspects before starting the injection mould engineering and construction stages.

Mould engineering and construction

Our in-depth knowledge of polymers allowed us to identify the plastics which best met the use and operating requirements of the sat nav device.

The external shells were made with a PC+ABS blend, a material which guarantees a good aesthetic result while at the same time being very resistant to high temperatures.

For the gaskets and the cable gland we used medium hard thermoplastic rubber (SEBS).

The choice of materials is always fundamental in the mould engineering stage as it allows us to accurately calculate the shrinkage (different from one plastic to another) and therefore to obtain moulded parts which meet the indicated size tolerances.

The task of making the moulds was assigned to Csplast: the strong interaction between our design and engineering team with the injection mould construction department allowed us to meet all the technical, aesthetic and economic requirements set out with Swarco Mizar, without wasting time and with no design flaws.

RESULT

The Roadrunner sat nav device came to life thanks to progressive work characterized by continuous refinement made possible by the overall vision of the project which our experts are able to offer and the constant collaboration with the client company. This synergy meant that during all the stages, from design through to production, we never lost sight of the stylistic and productive restrictions of the object which was able to pass all the type approval tests envisaged to become one of the best sat nav devices available on the market.

- ENGINEERING

- ENGINEERING

- PROGETTO STAMPO

- PROTOTIPI

- VERIFICA DIMENSIONALE PROTOTIPI

- TEST DI ASSEMBLAGGIO COMPONENTI

- NAVIGATORE IP65 CON GUARNIZIONI – PEZZO STAMPATO