| Case Study Technical Articles – MODULAR PLASTIC SCREW |

What is it

Archimedes’ screw is a simple system used to lift up a fluid or a sandy, pebbly, crushed material. The device consists of a screw (a helical surface surrounding a central cylindrical shaft) inside a hollow pipe. The bottom side of the hollow pipe is dipped into the material that has to be lifted up, then as the shaft turns, the bottom end scoops up a volume of product. This product will slide up in the spiral tube, until it finally pours out from the top of the tube and feeds the accumulation tank. Depending on the length and diameter of the screws, more than one screw could be used successively to lift the same product.

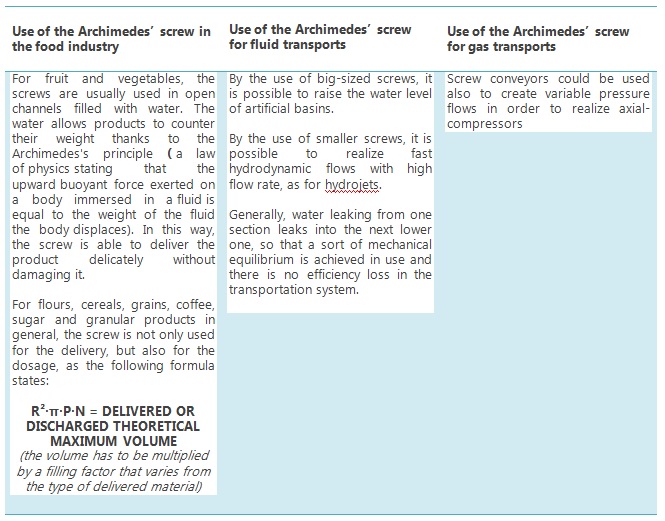

Uses

The transport of products through screw conveyor is used for a wide range of industrial fields and for substances in all the states of the material: fluid, solid or gaseous

Manufacturing technologies

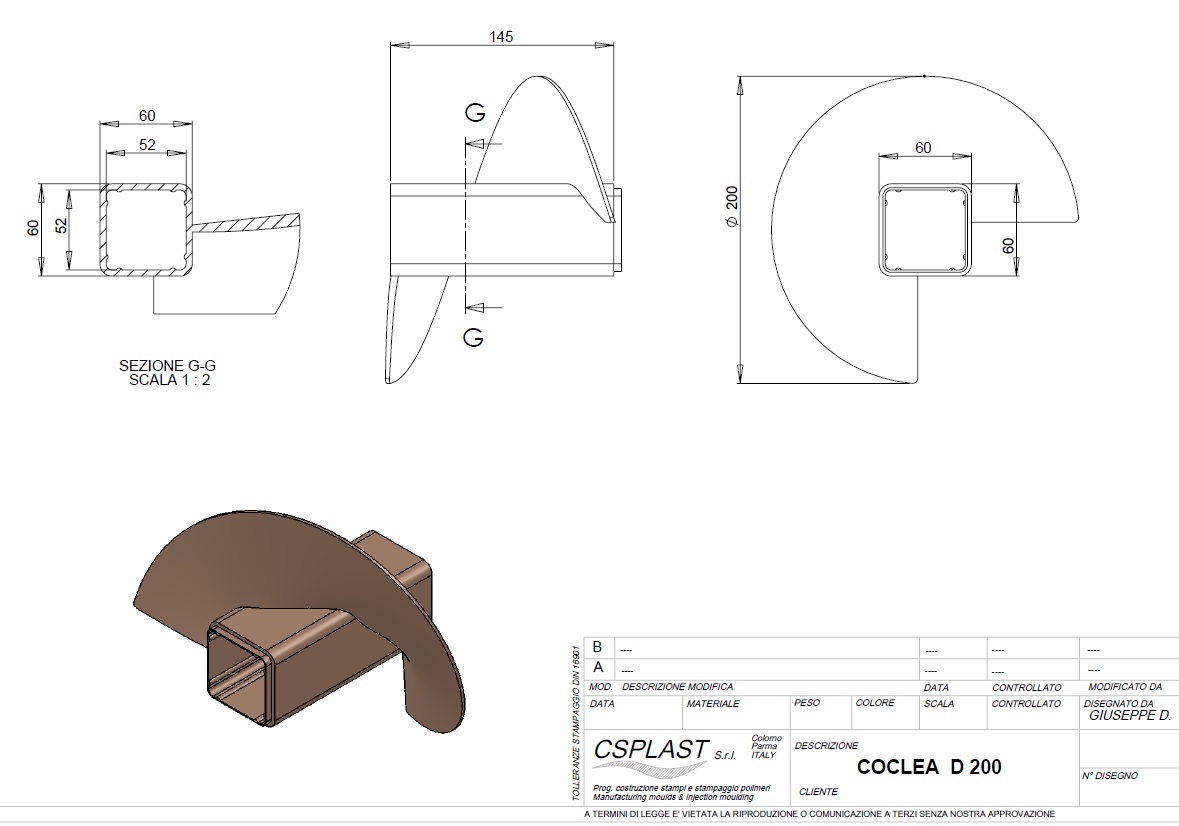

Screw conveyors are manufactured in different ways and materials. They could be casted as a single piece in steel or synthetic material, or the screws are fixed to the casing and they rotate together instead of the screw turning within a stationary casing.

Critical issues of use

Friction wear: due to the friction caused from the contact between delivered products and the boosting surface of the screws

Production cost: when the screw conveyor is realized by welding the screw to an axel, the production cost is very high. Moreover, once that the screws are worn, it is necessary to replace the whole system.

Plastic production advantages

CSPLAST’S MODULAR PLASTIC SCREWS

-

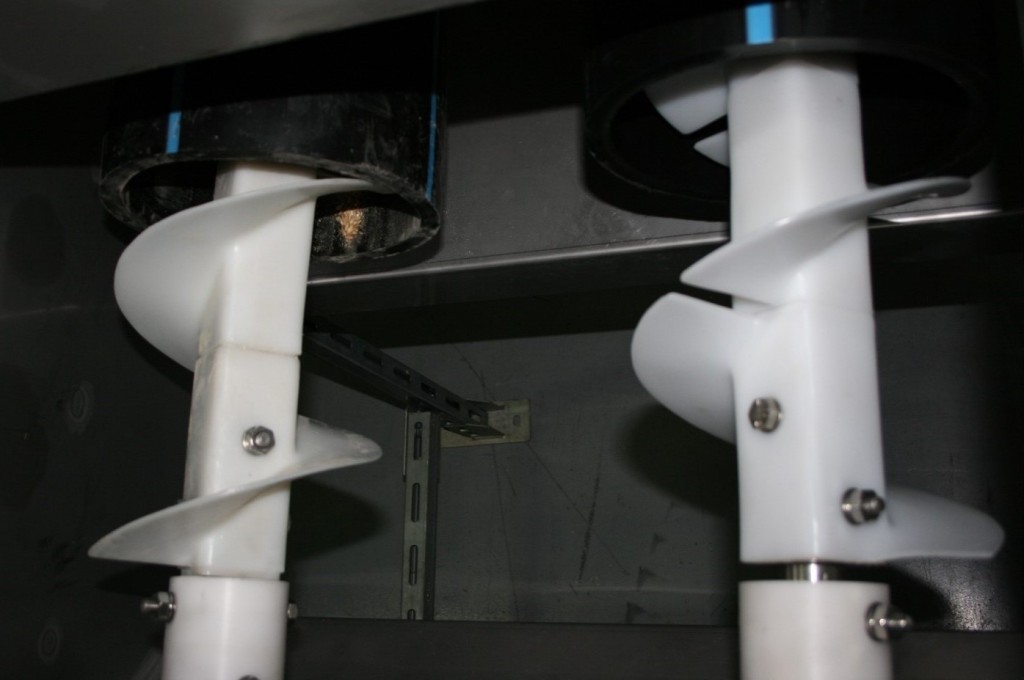

Wear-and-tear reduction: we realized our modular plastic screws by thinking that a lot of products are constantly exposed to friction (as the screws are). They reduce their wear-and-tear if realized with techno-polymers, as for example the steel pipes used for the sand transportation, that are usually worn into metal parts but not into rubbery parts

-

Supply, assembling and energy costs reduction: the use of Csplast modular plastic screw allow to considerably reduce costs for assembling by making it quicker. Moreover, there is a reduction of supply costs, since the plastic screws are more cheaper than the steel ones. Additionally, considering that the friction developed from plastic material is lower than the one produced by metal, there is also a remarkable decrease of energy costs.

-

Quicker and easier replacement: differently from metal screws, Csplast plastic modular screws are quickly and easily dismountable and replaceable during the maintenance work.

-

Suitable to be used where a magnetic field is required (screw conveyor sterilization): Csplast modular plastic screw can be used also when the transport of goods entail their sterilization (usually done with microwave frequency), given that we use a plastic that doesn’t absorb magnetic fields. So our screws don’t heat up during the delivery process and the delivered product is not damaged