|

|

Case Study Hand-held Sector – AUTOMOTIVE TESTER |

THE CHALLENGE

A company operating in the automotive sector, assigned us the task of developing a new project, giving us the opportunity to tackle a really stimulating challenge.

The experience of this company in the creation of analysis, diagnosis and roadworthiness servicing instruments for car workshops and their company concept linked to the needs of the vehicle repair worker, led to the need to conceive a new product for this sector: Memorex 2, a hand-held multi-brand self-diagnosis device with a wide cover for OEM systems and applications.

The essential objectives to reach were:

- to create a technologically advanced instrument;

- ease and comfort of use;

- sturdiness and resistance to the working environment of use;

- ensuring a look which conveyed a strong personality.

THE SOLUTION

Design

The project began in the design stage, in other words from the stylistic definition of the Memorex 2 hand-held device. One of the main requirements to be taken into consideration was the ergonomics of the appliance, which had to be easy to handle in all situations of use:

- on the workbench, providing a special docking station with recharge function;

- in the workshop, providing slots for a shoulder strap;

- on the steering wheel of the vehicle, thanks to the use of extractable supports.

What’s more, being as the hand-held device had to offer clear-cut technological innovation to the end market, it was important to consider what its different functions would be, so as a preliminary step we identified all those elements which would be installed in the casing (PCB and LCD boards, touchscreen, wireless connection systems, integrated camera, USB port, LEDs…). This step was fundamental for creating the geometries which could be functional to the engineering stages.

Despite the presence of numerous internal elements and their possible impact on the appearance of the shells, our designers met the objective of obtaining, from the very first photorealistic renderings, a project of great aesthetic impact. With this in mind, it was essential to opt for making the device with sections of rubber overmoulded onto the shells, which have made the object an even more eye-catching and comfortable to use device (easy to hold when wearing gloves and in workshop environments).

As well as the photorealistic renderings, at the end of this stage a resin study model was made so as to have, right from the beginning, a clear idea of the actual product, checking the ergonomic aspects and the real dimensions.

Engineering

Once the design phase had been approved we quickly continued to optimize the virtual geometries thanks to the experience of our team which contributed to speeding up the execution times while still observing the canons governing product quality.

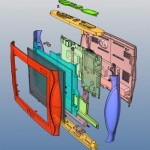

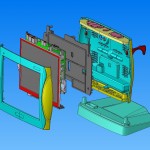

Through three-dimensional parametric modelling of the Memorex 2 we obtained the executive mathematics of all its elements: front and rear casings, sections of overmoulding, bottom and top faceplates, LCD support clamp, light guide and accessories.

Prototype

At this point we were able to give our client a fully functioning prototype, in which all the internal components were inserted for real product testing and to have feedback on its effectiveness from the market by initially exhibiting it at trade fairs. The creation of the prototype was carried out using stereolithography technology and Accura 25 material and Duraflex which made it possible to test the product not only from a functional point of view but above all from an aesthetic one.

Mould engineering and construction

After receiving confirmation on the effectiveness of the prototype, we went on to engineer the moulds, always taking into consideration all the design specifications defined by the client in the previous stages. The task of making the moulds was assigned to Csplast: the strong interaction between our design and engineering team with the injection mould construction department allowed us to meet all the technical, aesthetic and economic requirements set out with the client, Eos Motorscan, without wasting time and with no design flaws.

RESULT

The hand-held device came to life and became the exact product which we had imagined developing during that first meeting with the client, proving that the strong connection between our design and engineering team and the companies in charge of producing the moulds and carrying out moulding operations has a fundamental effectiveness.

- DESIGN

- DESIGN

- DESIGN

- ENGINEERING

- ENGINEERING

- MAQUETTE

- MAQUETTE BASE DOCKY

- PROTOTIPO – FRONTE

- PROTOTIPO – RETRO

- PROTOTIPO – GOMME

- PROTOTIPO – TEST DIMENSIONALI E INSERIMENTO COMPONENTI ELETTRONICI

- PROTOTIPO – TEST FUNZIONALI

- PROTOTIPO – TEST FUNZIONALI

- PEZZO STAMPATO E ASSEMBLATO

- PEZZO STAMPATO E ASSEMBLATO

- TESTER AUTOMOTIVE