Comoulded ferrule – Joint with metal insert – Safety valve

|

We have been designing technical components and articles in rubber and plastic on commission for all industrial sectors for over 30 years: this is why we understand the main requirements requested in this sector: articles must be effective and functional, long-lasting, easy to install and cheap. Our huge experience allows us to achieve the best solutions for each sector of competence, providing technical solutions which lead to excellent component efficiency, both from a performance and economical point of view.

When the technical articles to be designed are for installation in complex mechanical systems, we carry out feasibility studies and structural FEM (finite element method) analysis which gives us useful information on any deformation, stress or movements which may occur on plastic components so as to optimize engineering of the pieces. Whenever our reference is an object which already exists, we apply reverse engineering to digitalize physical objects so that the geometric surfaces can be analysed and remodelled on a computer.

In collaboration with the client we define the products’ project specifications (economic, dimensional, mechanical, technical and aesthetic) in observance of the required standards: EC ISO, UNI, IP. All those technical and functional aspects of the product are taken into consideration (operating requirements, mechanical loads, contact with specific substances, assembly or installation systems…) with the aim of providing an executive three-dimensional file which corresponds exactly with the project and can be used immediately to engineer the mould.

Metal/Plastic conversion

The activity we most frequently perform in this sector is the conversion of metal products into plastic ones: thanks to our many years of experience, our deep understanding of polymers (from the most common ones to super-polymers), together with our constant research and development activities within the scope of industrial plastic applications and the use of avant garde and innovative technologies, we can carry out feasibility studies on the possibility of transforming components traditionally made from metal into plastic components with the same characteristics and functions

The reproduction of a product in plastic represents a choice in favour of technological innovation which can bring with it numerous benefits, such as:

Speed of components assembly thanks to the use of interlocking parts and hooks which replace the use of fasteners

Lower maintenance costs

Reductions in transport and installation costs, thanks to the reduced weight of the components

Better aesthetics

Enviromental impact reductions, for example by eliminating the need to use toxic paints previously used for sheet metal parts

Our experience in the engineering of technical articles has allowed us to create components for many industrial sectors, such as:

Components for the mechanical sector

Components for the system engineering sector

Automotive components

Articles for the food industry

Articles for the building sector

Articles for the agricultural sector

Articles for the aerospace sector

Articles for the cosmetics sector

MEAT HOOK – Case study |

|

HAM MOULDS – Case study |

|

AEROPLANE PROPELLER – Case study |

|

MODULAR PLASTIC SCREW – Case study |

- Ingranaggio con rotella costampata

- Siringa per bicomponente

- Siringa per bicomponente

- Inserto costampato

- Giunto

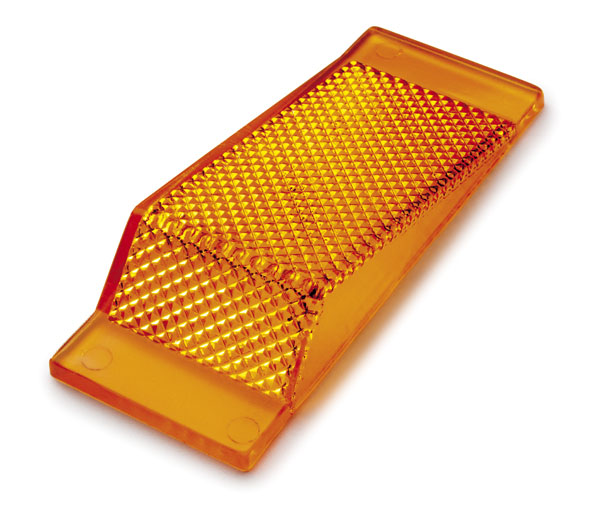

- Catarifrangente

- Catarifrangente

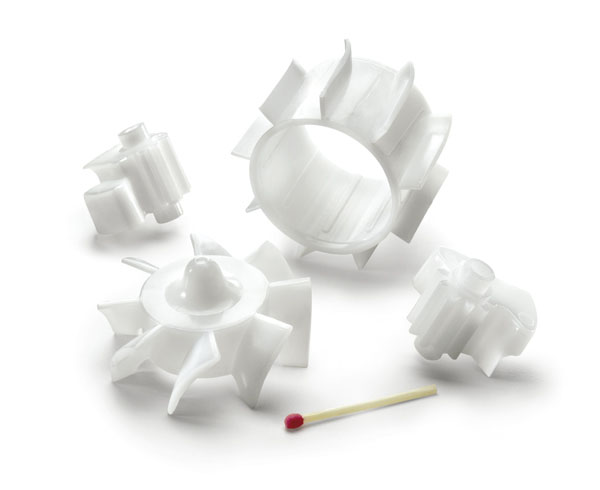

- Ingranaggi in plastica certificata per il contatto con alimenti

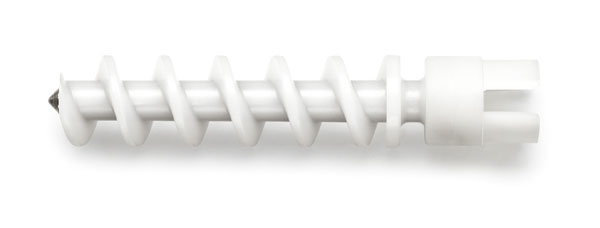

- Coclea per settore alimentare

- Ghiera costampata

- Raccordo settore meccanico

- Particolari cromati e dorati in fase di post-stampaggio

- Particolari tecnici in gomma

- Valvola

- Particolari per settore meccanico e impiantistico

- Rotelle saldate

- Particolari per settore agricolo e elettromeccanico

- Particolari per settore alimentare

- Soffione termico per settore meccanico

- Ingranaggi per settore alimentare

- Minuteria per settore meccanico

- Minuteria per settore medicale

- Valvola

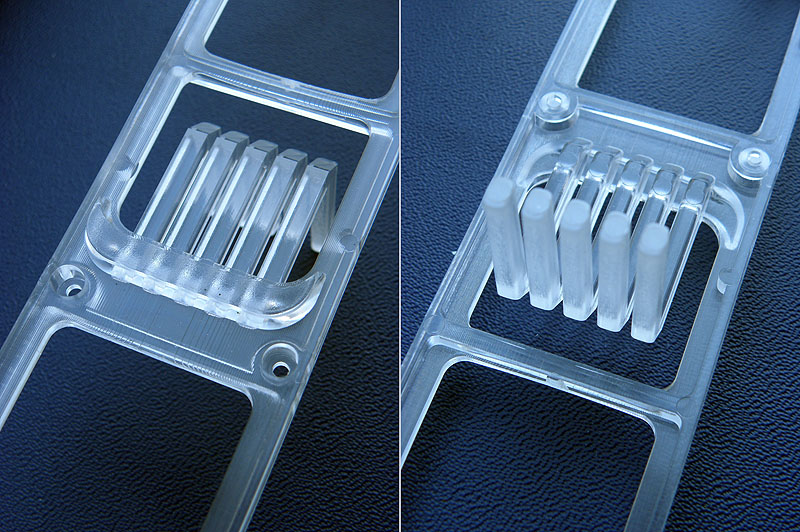

- Lente di Fresnel

- Sifone

- Portachiavi in gomma

- Portachiavi in gomma

- Guarnizioni in gomma

- Guarnizioni in gomma

- Angolari in gomma

- Guidaluce